How can we help?

So, you’ve come up with an idea. A tool, a learning aid, an ideal gift. Perhaps you have an exhibition in mind or want to make existing pieces more accessible?

You’ve maybe you’ve shopped around and found the thing you want doesn’t exist yet?

Well turning ideas into objects is the forte of 3D printing. And at Chapel Prints we’ve sold a lot of things that didn’t exist before we made them!

Not only do we have the tools, but also the skills and discipline to formalize your idea and make it in to a real world object!

Our Services:

Project Examples:

Learning aids for schools, unis, and homes.

Whether is a ribbon model of a DHFR protein or stoat’s skull; holding a model of the thing you’re talking about really can’t be beaten. The clarity and purpose a real world model gives to any lesson or discussion sharpens the focus and engages the intellect. Familiar with the rigors of academia, our models are sutied for the use of biologists, geologists, and even archaeologists.

Scanning and digitising.

Our structured light scanners are portable and disappointingly undramatic in size; but make up for it in their resolution. We can scan small objects down to a 0.2mm accuracy. Our larger scanner can input objects meters in length. Rendering the objects as a complete digital model takes some patience and time but this often an on-site service we can offer within the UK, paticularly around the North where we’re based.

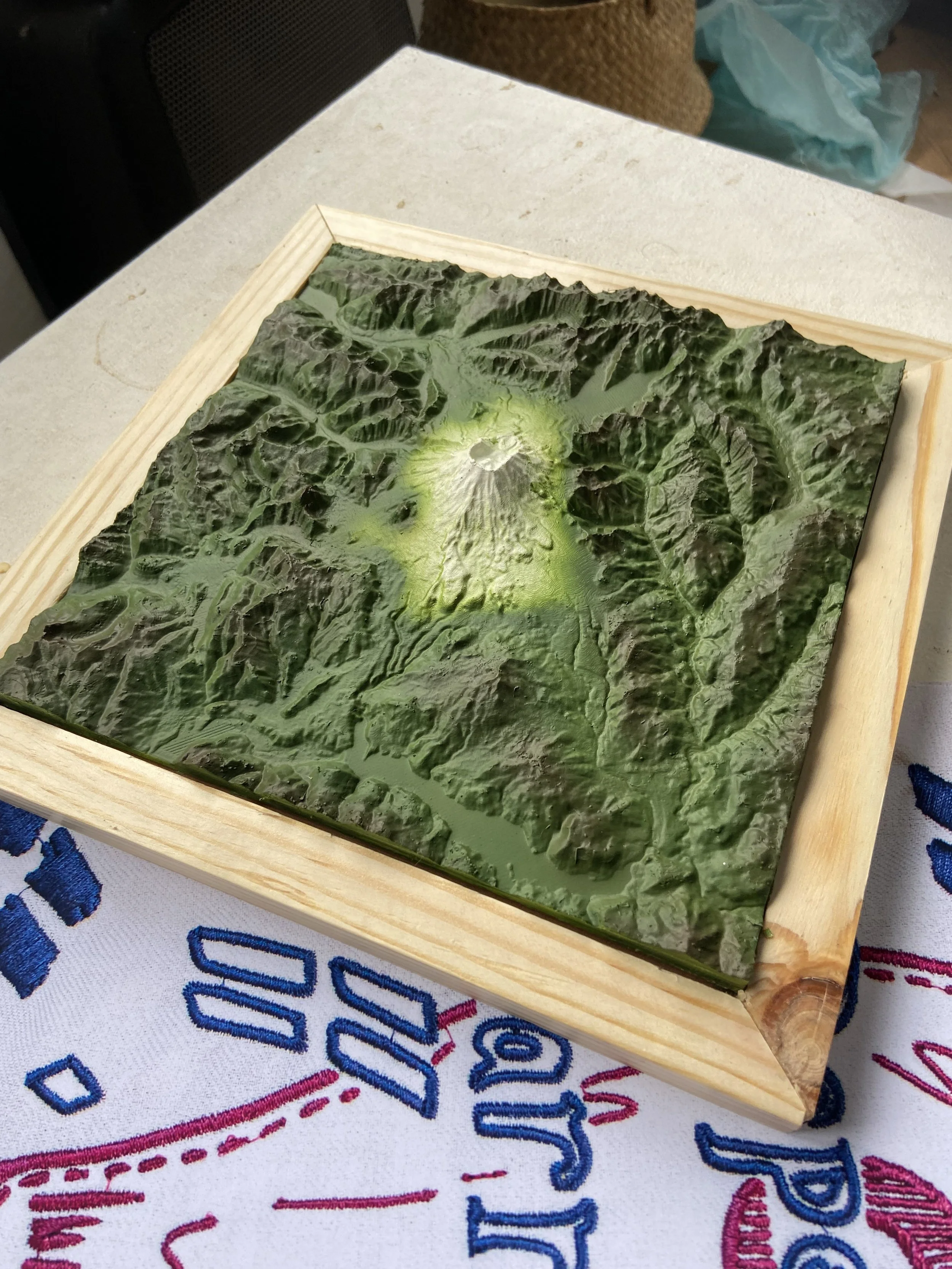

Commission piece maps.ff fffffffff

Topographical maps were something we started printing early on in our startup. We use various data sources working with tiff, asc, ply, and dem file types to name a few. Thanks to a recent explosion of available resources hardly anywhere on earth is unmapped. We’ve been moving away from map commission lately but do still consider medium and large prints and multiple orders.

Short production runs.

We’ve done various small production runs of items from wolf masks, to maps, to mini skulls. Our capacity runs to 100s not 1000s but we’re always willing to consider a project and think logistics. Usually, the bigger the order the cheaper the price - although we don’t compete with 3D printing houses directly as that's not quite what we do.

Commission moulds: positive and negative designs.

It’s much the same for us to create an inverse shape as it is an original positive design. inverting the surface on a topographical map or embossed design is relatively simple. We' also work with silicone rubber and specalist flexible filiments like TPU. We’re familar with pottery press and slip moulds and always keen to work with clay and potters when we can!

Design commissions.

We’ve helped clients design shower heads and mythical skulls, hinges and trail maps. We don’t claim to be engineering draftsmen but we can help with a very broad range or 3D designs and source data from a diverse array of libraries.